pilagou

Member

I need a somewhat specific case. It needs to be waterproof (I live on the West Coast, and it rains a lot), it needs to be tough (that accordion travels on a cargo bike) and it needs to be reasonably light and small (because why not). So I have a new project. I plan to built a custom fibreglass case and I'm looking for ideas and advice.

My current plan it as follow:

1) Build a rough model of my accordion out of cardboard. It won't be perfect but I want to get the keyboard angle and size within half an inch. Then wrap it in parchment paper (the thing used in baking)

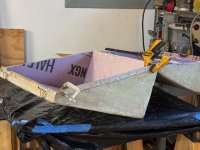

2) Add a layer of insulating board foam to create a foam shell around the cardboard model.

3) Shoot urethane foam on all the edges and connections and, once dry, carve the extra foam to get rounded edges and a good overall shape.

4) Hand lay the fibreglass directly on the foam (using epoxy). Probably something like 1/16 to 1/8 thick.

5) Once the fibreglass has dried, cut the whole thing in half along the keyboard line and remove the cardboard stub

6) Try the real accordion inside, carve the foam where and if needed. Add some urethane if and where needed

6) Rivet a sandwich of thin aluminum plates all around, a piano hinge on the back and some clamp catches on the front

7) Glue a thin layer of soft foam on the inside and then some velvet on the foam.

and that's it

I have some experience working with foam, fibreglass and metal. But that would be my first music instrument case. Anyone sees flaws or areas for improvement in that plan? I expect the whole project to be between $200 and $300

My current plan it as follow:

1) Build a rough model of my accordion out of cardboard. It won't be perfect but I want to get the keyboard angle and size within half an inch. Then wrap it in parchment paper (the thing used in baking)

2) Add a layer of insulating board foam to create a foam shell around the cardboard model.

3) Shoot urethane foam on all the edges and connections and, once dry, carve the extra foam to get rounded edges and a good overall shape.

4) Hand lay the fibreglass directly on the foam (using epoxy). Probably something like 1/16 to 1/8 thick.

5) Once the fibreglass has dried, cut the whole thing in half along the keyboard line and remove the cardboard stub

6) Try the real accordion inside, carve the foam where and if needed. Add some urethane if and where needed

6) Rivet a sandwich of thin aluminum plates all around, a piano hinge on the back and some clamp catches on the front

7) Glue a thin layer of soft foam on the inside and then some velvet on the foam.

and that's it

I have some experience working with foam, fibreglass and metal. But that would be my first music instrument case. Anyone sees flaws or areas for improvement in that plan? I expect the whole project to be between $200 and $300