Photo 2: we removed the panel and had a sinking feeling at the apparent complexity of the bass machine

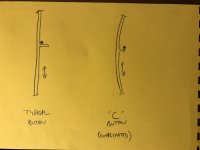

… the C piston has a slight bow and only just connects with the rod - a little sideways movement and it will slip off

It's back together and working - but I'm sure it will go again. I did try bending the piston but there's not really enough room to work.

Excellent start! Isn’t the thing amazing and wonderfully complex! Someone described the bass machine as an incredible complex mechanical computer, and think of how many years ago this technology was developed. The inside of my accordion reminded me vaguely of the complexity of the technology in a player piano I rebuilt decades ago - technology invented over 100 years ago. And we think we’re so clever today!

I don’t know where you and others could find them but I keep a drawer full of special tools just for working in sometimes very tight places. A few years ago someone from the hospital had taken a box of surgical tools to a local metals recycling place. This place is unusual since the will let you pick through things and only charge scrap prices based on weight.

The tools were stainless steel, titanium, etc., some with gold plating on working ends. The haul contained a variety of gripping tools (hemostats, tiny pliers, special long-reach grabbing tools), cutting tools such as long tiny scalpels and scissors (one with tiny blades intended for eye surgery), small hammering rods, and much more. Some tools are bent and shaped in unusual ways, often perfect to reach that impossible spot. There were so many tools I gave away a bunch, some to a veterinarian friend, and kept what I imagined might be useful some day. And they have been - just last week I was working deep inside a tight electronic control box and had just what I needed to grip and bend and reassemble.

Someone interested in delicate repairs might make contact with a local hospital and see if they also throw away used surgical tools. (All are sterilized, BTW)

I also make special tools as needed. For bending small metal parts for adjustment sometimes just a simple steel rod with a slots cut into the sides or ends can do the trick - sometimes use two tools at once, one to stabilize to prevent incidental damage and the other to apply the force in the right place. If you could use tools like that to work on your accordion and don’t have a way to make them perhaps a local “tinkering” friend has the resources and knowhow. I and some friends keep metal-working tools (mill, lathes and such) as well as welding equipment. If I can’t fix it my buddy Joe prob can! Mostly we like to work on small things but being able to repair big equipment too is useful around the farm! And it’s all good fun.

(I too am fortunate to have an expert accordion repair person, this one local, willing to take the time to teach me to diagnose and make adjustments and repairs. AND give me accordion lessons and encouragement! We spent some time today on fingering for stradella scales and techniques for “walking bass“. SO much to learn, so little time…)

JKJ