Ah, I've been working hard on accordion for the last few weeks for a carol performance this morning. But I only managed one tune before a treble pallet came loose and my Concerto started sounding a continuous E note.

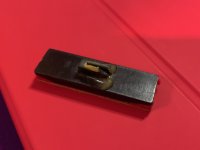

Back home I put it back in place for some photos, it's the left hand red-felted pallet. Nearly all the pallets have white felt, but two have been re-felted in red, or maybe replaced. It looks like by someone not particularly skilled as both show signs of the black plastic having been melted. I'm wondering if maybe a soldering iron has been used directly to melt the wax. Either way, it's going to need a repair

I also realise that my Weltmeister 48 that's not been played recently doesn't have the range to play much of my new repertoire so I'm not stuck without an instrument over Christmas. It may be time to think about a new accordion. I was looking at a Hohner Atlantic a couple of weeks ago...

Back home I put it back in place for some photos, it's the left hand red-felted pallet. Nearly all the pallets have white felt, but two have been re-felted in red, or maybe replaced. It looks like by someone not particularly skilled as both show signs of the black plastic having been melted. I'm wondering if maybe a soldering iron has been used directly to melt the wax. Either way, it's going to need a repair

I also realise that my Weltmeister 48 that's not been played recently doesn't have the range to play much of my new repertoire so I'm not stuck without an instrument over Christmas. It may be time to think about a new accordion. I was looking at a Hohner Atlantic a couple of weeks ago...