Before watching this film, I had considered building my own bellows.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

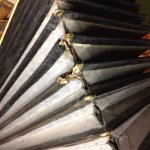

Bellows construction

- Thread starter artelagro

- Start date

- Status

- Not open for further replies.

Wow this is quite the video. Very interesting. I watched it, and can really appreciate how much skill went into making them, as well as the entire accordion. Think about in the day too when everything was made by hand.

P

psc945

Guest

What type of card is it to start with, how thick is it. where can you get this basic folded card from?

Paul C

Paul C

P

psc945

Guest

Looking at that video referred to above it has 20 folds. is this standard?. My Rossini has 16. They obviously vary a little.

It appears they vary in the way they are lined and trimmed to.

Paul C

It appears they vary in the way they are lined and trimmed to.

Paul C

Hi Paul,

In the UK Charlie Marshall at http://www.cgmmusical.co.uk/ lists the folded card under Assorted Parts

Garth

In the UK Charlie Marshall at http://www.cgmmusical.co.uk/ lists the folded card under Assorted Parts

Garth

If you buy the folded card and other materials, metal bellows corners in particular, at retail prices the total cost soon makes complete bellows look like good value!

No criticism of Charlie Marshalls prices, but hes maintaining a big variety of parts for people who are doing repairs.

I made a set of bellows for a small diatonic accordion a few years back. They turned out fine and worked well. I folded my own grey boardto start with.

I wrote about the process on melodeon.net several years ago if anyone is interested, and others there have probably written about bellows making.

http://forum.melodeon.net/index.php/topic,1958.msg19449.html#msg19449[/url]

Tom

No criticism of Charlie Marshalls prices, but hes maintaining a big variety of parts for people who are doing repairs.

I made a set of bellows for a small diatonic accordion a few years back. They turned out fine and worked well. I folded my own grey boardto start with.

I wrote about the process on melodeon.net several years ago if anyone is interested, and others there have probably written about bellows making.

http://forum.melodeon.net/index.php/topic,1958.msg19449.html#msg19449[/url]

Tom

I think counting valleys is the best way of avoiding confusion. :shock: :?Soulsaver said:They do vary, I have accordions with 16, 17 , 18 and 19 folds (corners). .. And just to be pedantic, in frame at 9:33 I count 19 corners... 18 valleys.

I think counting valleys is the best way of avoiding confusion. :shock: :?Soulsaver said:They do vary, I have accordions with 16, 17 , 18 and 19 folds (corners). .. And just to be pedantic, in frame at 9:33 I count 19 corners... 18 valleys.

Got you covered then, Tom... and anyone who counts corners :tup:

- Joined

- Apr 30, 2013

- Messages

- 5,197

- Reaction score

- 1,020

With the Ebay add's offering to build a set of bellows to fit what you need, and if you spend the the time to use the web to find a good replacement set, I can't see no practical or financial reason to even attempt to build yourself a set of replacement bellows. This cardboard you purchase will require you to line them with cloth glued internally and externally, fitted with bellows corners, and then bellows tape applied. The cost of materials - card board- cloth - glue- bellows corners-bellows corners diamonds (kid skin) -bellows corner tools - and time consumed- might in almost most cases, just exceed the value of the accordion itself. Just the cost of a set of bellows corner tools alone will cost you more than a set of bellows.

P

psc945

Guest

Yes I did try to count Tops of folds. Valleys may be the better way.

I am hoping to learn from the experience. it would probably be a one of, I understand it may be expensive, trying to cost it out first to see how 'cheap' I could do it for. There doesn't seem to be much basic materials out there to chose from. The main questions that come to mind when looking at the bellows material, is what are the materials used, such as the correct card, acoustic qualities, temperature or water resistance, or do the Italian companies use ordinary drawing office card. Have seen some Videos of the metal corners just glued in place, I would have thought they would be better crimped in place as you suggest. That may be an expensive route if crimping is necessary.

The Accordion I was going to practice on is a Settimio Soprani, an old one, not sure of age possibly 1940 - 1950. I might set up a thread with the pictures of it as I have stripped it down. To have it repaired would be more than a decent modern Italian unit.

I was hoping to learn and not worry about whether it is a good finished product. Yet it will be difficult for me to allow that to happen. However the only thing I feel I will not be able to probably do is tune the reeds at the point it will need it.

I think the best thing will be to post pics and see what comments come in.

If it just shows me how they work in detail I will be happy I have learnt something. If I can end up with an instrument that works, even out of tune, I will be ecstatic, obviously not my main Instrument so will not be punishing others with it.

The cost is a consideration yes. Learning about the way they work is more important.

How can I post pics, was thinking of using photobucket. Or is there alternatives prefered on this forum.

I am intending to just going to enjoy the journey.

Paul C

I am hoping to learn from the experience. it would probably be a one of, I understand it may be expensive, trying to cost it out first to see how 'cheap' I could do it for. There doesn't seem to be much basic materials out there to chose from. The main questions that come to mind when looking at the bellows material, is what are the materials used, such as the correct card, acoustic qualities, temperature or water resistance, or do the Italian companies use ordinary drawing office card. Have seen some Videos of the metal corners just glued in place, I would have thought they would be better crimped in place as you suggest. That may be an expensive route if crimping is necessary.

The Accordion I was going to practice on is a Settimio Soprani, an old one, not sure of age possibly 1940 - 1950. I might set up a thread with the pictures of it as I have stripped it down. To have it repaired would be more than a decent modern Italian unit.

I was hoping to learn and not worry about whether it is a good finished product. Yet it will be difficult for me to allow that to happen. However the only thing I feel I will not be able to probably do is tune the reeds at the point it will need it.

I think the best thing will be to post pics and see what comments come in.

If it just shows me how they work in detail I will be happy I have learnt something. If I can end up with an instrument that works, even out of tune, I will be ecstatic, obviously not my main Instrument so will not be punishing others with it.

The cost is a consideration yes. Learning about the way they work is more important.

How can I post pics, was thinking of using photobucket. Or is there alternatives prefered on this forum.

I am intending to just going to enjoy the journey.

Paul C

- Joined

- Apr 30, 2013

- Messages

- 5,197

- Reaction score

- 1,020

With all respect, you are attempting to bite off more than you can chew and afford. Sorry but thats the Straight Skinny. But I do appreciate your endeavor . Ive been at this for at very possibly before you were born. The components you need to build a set of bellows will require materials and tools that will in all cases far outweigh the cost of the instrument you wish to resurrect. But I admit that stubbornness can be a virtue, and for some reason you wish to continue with this endeavor, their are some of us old farts on this Forum that have experience and will work you thru it.

P.S. Im from across the pond and aware that the only thing that separates us is a common language so to explain my use of Straight Skinny see here --

http://www.urbandictionary.com/define.php?term=straight skinny

And I almost forgot! WELCOME your gonna like it here. :tup: {} :tup:

P.S. Im from across the pond and aware that the only thing that separates us is a common language so to explain my use of Straight Skinny see here --

http://www.urbandictionary.com/define.php?term=straight skinny

And I almost forgot! WELCOME your gonna like it here. :tup: {} :tup:

With great respect to Jim, whos a professional, I will say that decent bellows can be made with just ordinary household and woodworking tools. I know, Ive done it - viz my melodeon.net link above. I had to make various jigs etc along the way, but they were straightforward to make out of wood. When folding the card I used a couple of g-clamps to give it a hard squeeze. I should have used little pieces of silk cloth to link the corners until the leathers were on. The size I was making I was able to get two leather corners out of one as sold by Charlie Marshall. Buying a piece of suitable leather would be much cheaper. I made a little jig to support a corner while gluing the leather corner. I crimped the metal corners using pliers. Etc.

The diatonic button accordion/melodeon makers tend to work on a craft basis compared with the more factory based setup of the PA and CBA makers, so their websites can be worth a look. I learned a lot from Olav Bergflodts workshop pictures.

http://www.bergflodt.net/

This video makes hand building bellows look very easy!

The diatonic button accordion/melodeon makers tend to work on a craft basis compared with the more factory based setup of the PA and CBA makers, so their websites can be worth a look. I learned a lot from Olav Bergflodts workshop pictures.

http://www.bergflodt.net/

This video makes hand building bellows look very easy!

Hi Paul, If I didn't say welcome elsewhere... welcome. Photobucket is fine. Or on here, when you hit the 'post reply', scroll down a bit and bottom left below the 'pane' see the 'upload attachment' option. If it 'fails', your pic will be too big and will need to be reduced in your camera/phone/ pc pic editor.

P

psc945

Guest

Thanks, I can accept criticism along with any help. Thanks for the frank advice. I think I may be biting off more than I should. Still willing to learn from others. If the cost starts to rise my better half will throw it in the bin or my suitcase will be on the doorstep.

P

psc945

Guest

P

psc945

Guest

psc945 said:If the cost starts to rise my better half will throw it in the bin or my suitcase will be on the doorstep.

They keep it in perspective... dont they?

P

psc945

Guest

Reeds

Not too rusty but must be some way to take of the rust without effecting pitch too much.

Some are pretty clean too. A mix. The leathers have curled and some of the supports fallen away.

Not too rusty but must be some way to take of the rust without effecting pitch too much.

Some are pretty clean too. A mix. The leathers have curled and some of the supports fallen away.

Attachments

Might be worth trying ACF-50 on a cotton bud.

It certainly stops corrosion and, in my experience - not on accordion reeds - removes rust without further surface damage.

It is a touch pricey - but its good for bikes and lawnmowers too....

It certainly stops corrosion and, in my experience - not on accordion reeds - removes rust without further surface damage.

It is a touch pricey - but its good for bikes and lawnmowers too....

- Status

- Not open for further replies.

Similar threads

- Replies

- 19

- Views

- 264

- Replies

- 11

- Views

- 363