Was looking to see if I could see anything about which reed valve was giving trouble in my accordion. Opened it up and went as far as pulling one reed block to see a little better, a pretty simple matter, or so I thought.

Loosening one end of the reed block didn't feel sufficient to me, so I, with some force on a hand screwdriver only, it is to be admitted, loosened the other end, which is part of the mechanism that holds the bass register pivot. Unfortunately I did not have "epoxy-fixed screw" in my list of reasonably likely things to find in a good accordion I bought new and has only been tuned once by Guenadiy himself.

Long story short, the screw in question broke off within the brass standoff.

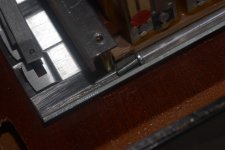

Two pictures of that.

On the other side, I can't see the specific screw very well, but I have a picture of the nut for the other screw on that bar.

Also included are pictures of each end of the bass machine.

I'm guessing a proper repair means matching the screw, and hopefully I can get the standoff out of there, get vise grips and perhaps some solvent on it, and unscrew the remains for replacement. Short of that, am I looking at a full bass machine disassembly to get at the other side, figure out how to remove the screw and washer - possibly putting it in my small bench mill with a long end mill, and grinding it away at the worst case to not damage the wood?

For repair, two questions:

One, what is the easiest and fastest way to get myself safe to play that won't have (probably) me furious with myself at proper repair time. CA or epoxy the remains of the screw in place? Other?

Two, what is the best proper fix?

Edit: Also have another accordion, an older 2/4 that needs an overhaul. Not worth it financially/time, I know, but it's somewhat special to me, so I've been planning to make a learning project of it. Was going to order from FRM, but he seems to have closed. Where is the next best place to order supplies in the US?

Loosening one end of the reed block didn't feel sufficient to me, so I, with some force on a hand screwdriver only, it is to be admitted, loosened the other end, which is part of the mechanism that holds the bass register pivot. Unfortunately I did not have "epoxy-fixed screw" in my list of reasonably likely things to find in a good accordion I bought new and has only been tuned once by Guenadiy himself.

Long story short, the screw in question broke off within the brass standoff.

Two pictures of that.

On the other side, I can't see the specific screw very well, but I have a picture of the nut for the other screw on that bar.

Also included are pictures of each end of the bass machine.

I'm guessing a proper repair means matching the screw, and hopefully I can get the standoff out of there, get vise grips and perhaps some solvent on it, and unscrew the remains for replacement. Short of that, am I looking at a full bass machine disassembly to get at the other side, figure out how to remove the screw and washer - possibly putting it in my small bench mill with a long end mill, and grinding it away at the worst case to not damage the wood?

For repair, two questions:

One, what is the easiest and fastest way to get myself safe to play that won't have (probably) me furious with myself at proper repair time. CA or epoxy the remains of the screw in place? Other?

Two, what is the best proper fix?

Edit: Also have another accordion, an older 2/4 that needs an overhaul. Not worth it financially/time, I know, but it's somewhat special to me, so I've been planning to make a learning project of it. Was going to order from FRM, but he seems to have closed. Where is the next best place to order supplies in the US?

Attachments

Last edited: