Ventura

Been here for ages!

maybe try and look at this from the perspective of the steel

in theory and process, certainly you should be able to make

damn close to identical spec wide and thin sheets of steel

including their temper

but in practice a coil that runs through an old-style rolling mill

designed and dedicated to coils has a finer ability to control

saturated temperatures and the timed control needed for closely

held tempering, as well as being able to offer many incremental

levels of thickness to reduce the need for sanding the steel to

control basic pitch for reeds using the same size aluminum plate

you also have to consider, from the point of the steel, whether

various methods of cutting the steel to size has an effect on the

steel itself.. does the grain get stretched along an edge that is cut

by a shear more than if a tongue is punched out, and does the

intensity of a punch cause microscopic fracturing in the steel

especially if the punch does not hit the entire piece of steel exactly

every time.. if you go whole hog and cut the tongues through a plazma

or lazer cutter process, you eliminate those types of distortion, but

induce intense heat along the edge which will affect the temper

in other words, the LESS you MESS with the steel the better, so a coil

source, i feel, will always produce a more pristine reed-tongue with less

changes induced in the steel through the final shape cutting process

also, the company cutting all reedtongues out of one thickness

steel sheet is at a huge disadvantage compared to a company that

purchases reed coils in many different thickness

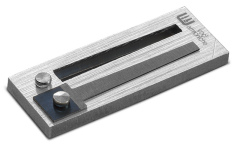

and don't forget the quality of the aluminum plate, the duraluminum

type allowing for sharper cleaner edges and greater strength to receive

and work with the steel tongue in perfect harmony with optimum tolerance

these processes are largely fully automated at this point in time,

so first, after the huge pile of tongues have been cutout, you would

have some automated process that sorts them onto grades of

perfection, and the ones most perfectly to spec will get paired

with the best aluminum plates and then assembled..

again, there will be some assembled reedpairs more perfect than others,

so again some process to measure and sort.. when you get it down to

the best ones, now humans put hands on them and finesse them..

we all know the more time you put into the reeds and tuning the

better the result

so until humans put hands on them whatever category they fall into,

whatever name or term the company wants to theoretically assign

to them, there really isn't much physical difference between cheaper

reeds and the most expensive ones if all of them start with the

same sheet of steel

then what design is used ? we have all seen cheaper accordion reedblocks

where it looks like 8 or 9 reedplates next to each other the exact same

size, so obviously at least 7 of those reedpairs are LESS than optimally

sized regarding the steel reedtongue.. if you look inside the highest priced

model, how close will you get to 65 unique different treble size reedplates

and tongue pairs ? remember, the LESS you MESS with the steel the better

so if you figure out your specs exactly and can use a coil of steel the

exact thickness the reedtongue will end up being at pitch the human

can then spend their time finessing the exact position of the steel in

the plate and need a minimal removal of steel for the final tuning

in theory and process, certainly you should be able to make

damn close to identical spec wide and thin sheets of steel

including their temper

but in practice a coil that runs through an old-style rolling mill

designed and dedicated to coils has a finer ability to control

saturated temperatures and the timed control needed for closely

held tempering, as well as being able to offer many incremental

levels of thickness to reduce the need for sanding the steel to

control basic pitch for reeds using the same size aluminum plate

you also have to consider, from the point of the steel, whether

various methods of cutting the steel to size has an effect on the

steel itself.. does the grain get stretched along an edge that is cut

by a shear more than if a tongue is punched out, and does the

intensity of a punch cause microscopic fracturing in the steel

especially if the punch does not hit the entire piece of steel exactly

every time.. if you go whole hog and cut the tongues through a plazma

or lazer cutter process, you eliminate those types of distortion, but

induce intense heat along the edge which will affect the temper

in other words, the LESS you MESS with the steel the better, so a coil

source, i feel, will always produce a more pristine reed-tongue with less

changes induced in the steel through the final shape cutting process

also, the company cutting all reedtongues out of one thickness

steel sheet is at a huge disadvantage compared to a company that

purchases reed coils in many different thickness

and don't forget the quality of the aluminum plate, the duraluminum

type allowing for sharper cleaner edges and greater strength to receive

and work with the steel tongue in perfect harmony with optimum tolerance

these processes are largely fully automated at this point in time,

so first, after the huge pile of tongues have been cutout, you would

have some automated process that sorts them onto grades of

perfection, and the ones most perfectly to spec will get paired

with the best aluminum plates and then assembled..

again, there will be some assembled reedpairs more perfect than others,

so again some process to measure and sort.. when you get it down to

the best ones, now humans put hands on them and finesse them..

we all know the more time you put into the reeds and tuning the

better the result

so until humans put hands on them whatever category they fall into,

whatever name or term the company wants to theoretically assign

to them, there really isn't much physical difference between cheaper

reeds and the most expensive ones if all of them start with the

same sheet of steel

then what design is used ? we have all seen cheaper accordion reedblocks

where it looks like 8 or 9 reedplates next to each other the exact same

size, so obviously at least 7 of those reedpairs are LESS than optimally

sized regarding the steel reedtongue.. if you look inside the highest priced

model, how close will you get to 65 unique different treble size reedplates

and tongue pairs ? remember, the LESS you MESS with the steel the better

so if you figure out your specs exactly and can use a coil of steel the

exact thickness the reedtongue will end up being at pitch the human

can then spend their time finessing the exact position of the steel in

the plate and need a minimal removal of steel for the final tuning

Last edited: