You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fast keyboard?

- Thread starter Neoscan

- Start date

Great- I was worried a chainsaw would be overkill but a crowbar sounds just about right for the job! I’ll save the chainsaw for working on the reeds at a later date.Chainsaw? Really!!

You know @tcabot, I despair sometimes about these unhelpful comments of yours.

Sheesh! We both know all that's needed here is a crowbar with a bit of heft behind it, that'll loosen them stiff old keys.

Thanks- this is the answer I was looking for and had thought that somehow lighting the wood under the key would help with lightening the response. Drill would be the easiest way to do this as you suggest but still quite a large undertaking. If I can’t get used to this keyboard though more use I’ll definitely look into this idea more. Thanks! Makimg magnesium arms- now that’s serious effort!The real way to speed up a keyboard is to change the mass of the keys. This includes the arm and the pad. i have seen a lot of different ways to do this.

Some really nice instruments I saw in the past had the wood understructure drilled out like a aircraft strut. I messed around with making arms out of magnesium but this would require hot working the keyboard during construction and the logistics of running a machining operation dealing with the shavings. I have done this but it requires a sort of intense vigilance to avoid fires.

Leverage angle is also a factor but the design of an accordion is a series of compromises and to gain something you usually have to give up something.

I have had customers that want a really shallow key travel , but the lack of pad lift becomes a breathing problem for the low octave reeds that need more air. You can use a bar linkage to deal with this (you see this on better instruments that have a white key operating a pad on the sharps reedblock) but this can have problems with linkage noise, and adds mass.

I don’t think any change to the keyboard will enable me to play faster but was hoping to make the key response faster/lighter. This won’t affect the speed of the music played but will help with fast machine-gun-like double triplets etc when playing hopefully.If that really was the way to have a fast playing keyboard I wonder what drug it takes to play ultra-fast pieces on a (grand)piano?

Compared to these hammer mechs our keyboards are super light and offer much less key travel and force.

But how many accordionists can keep up with a very good piano player - even if you give them the fastest accordion keyboard?

There must be something else than keyboard-material and mechanics

Ventura

Been here for ages!

i have noted the pivot rod(s) in (at least some) Dallape and Excelsior modelsLeverage angle is also a factor but the design of an accordion is a series of compromises and to gain something you usually have to give up something.

were very thin compared to the thick/fat pivot rods on most brands, which

seems to me to shift the fulcrum point favorably for speed and sensitivity

in our favor.. this allows i believe a cleaner angle of lift (more parallel to the hole)

there was a top model Bell Duovox, built for them by Galanti, that had a slightly

longer keylength than typical pro accordions and i have noted a longer key on

some pre-war accordions too, again i feel this gained an advantage re: the pivot point

I have had customers that want a really shallow key travel , but the lack of pad lift becomes a breathing problem for the low octave reeds that need more air. You can use a bar linkage to deal with this (you see this on better instruments that have a white key operating a pad on the sharps reedblock) but this can have problems with linkage noise, and adds mass.

have mentioned in the past how incredibly precise the pads are on my

960.. sized and fitted perfectly so that they lift and allow air immediately,

as there is no wasted overlap on the edges around to force a higher lift

of the pad to achieve necessary flow to sound the reed accurately

this was achieved by their mechanism being stronger in resisting side to side

play allowing them to be that precise, as well as their assembly skill back

in the day, Together they allow the most advantageous angle of lift with

the swiftest full airflow

bottom line is the action is far shallower on my 960 yet more responsive than

most of it's contemporaries built at that period

not all pro models from CEMEX had this action, it was a special order

or premium build

for this thread, however, we still have no idea what model/brand his original

exposure to "speedy action" was "set" by, nor what brand or model he

is currently slightly displeased with.. the engineering behind these models

may be the limiting factor for his issue

If that really was the way to have a fast playing keyboard I wonder what drug it takes to play ultra-fast pieces on a (grand)piano?

Compared to these hammer mechs our keyboards are super light and offer much less key travel and force.

As a piano player for around 60 years, that was my exact thought when I read this thread. Piano keys take significantly more pressure than those I’ve tried on accordions, organs, and most electronic keyboards. The weight” difference between various pianos can vary but most seem close, whether upright or grand. (I have a Baldwin grand) With enough practice and finger training, the piano can be played VERY fast!

Unlike typical electronic keyboards and accordions heavier keys on a piano are actually needed to give the player fine control over the dynamics to allow playing very soft or very loud - sometimes different keys are played to sound different loudness at the same time, either with separate hands or even with different fingers on the same hand.

When I first tried an electronic keyboard I found it horrible because the key weight was so light. When I bought good electronic keyboards I got some with weighted keys (a Kurzweil Midiboard and a Yamaha KX88). They don’t have the same feel as a piano but are far better than the typical lightweight keys. These keyboards control dynamics (loudness) with speed sensors instead of a mechanism so they are not quite the same as a piano but are much better than those with unweighted keys.

I’m certain my various piano teachers’ response to keys feeling too heavy would certainly have been the same as for other “problems” - practice, more practice!

As a beginner with accordion I find the transition from the piano difficult due to both the orientation (vertical), key lightness, and especially the narrow widths of the keys - the intervals have much different spacing! It’s challenging to switch from one to the other, but I refuse to give up. I’m sure the answer is still “more practice”.

As expected, the fingers, hands, and to some extent the arms do get stronger with more use. I often surprised the macho guys with tiny brains who thought it fun to try to crush the other’s hand in a surprise strength contest!

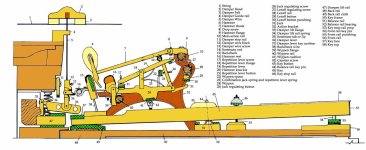

BTW, for anyone interested, here are diagrams of key mechanisms in a grand and an upright piano. Much of the complexity is to allow fine control of the dynamics but some is to lift the damper off the string.

Like accordions, these mechanisms sometimes need adjustments and parts like felts replaced. Good piano technicians are well respected!

JKJ

Ventura

Been here for ages!

the difference in Grand vs: Upright piano action..

as you can see from these diagrams, only gravity is needed

to return the hammer on a Grand.

the digital high-end brands have borrowed from grand Piano actions

in many ways.. some using a truncated but legit design, a few the full

key-length action

it is actually easy to unbolt and slip a Grand action out for study

and comparison.. like Accordions, actions can "look" much the same

but there are serious differences between good ones and great ones

as you can see from these diagrams, only gravity is needed

to return the hammer on a Grand.

the digital high-end brands have borrowed from grand Piano actions

in many ways.. some using a truncated but legit design, a few the full

key-length action

it is actually easy to unbolt and slip a Grand action out for study

and comparison.. like Accordions, actions can "look" much the same

but there are serious differences between good ones and great ones

My point may have been missed- I’m not talking about being able to play faster. I’m talking about the fastness/speed of the response of the keyboard and if it’s possible to improve or modify it. Yes, I can just learn to live with it and get used to it as with any instrument.As a piano player for around 60 years, that was my exact thought when I read this thread.

I’m very aware of how fast pianos can be played. Playing a light weight electric keyboard after playing a high quality grand it a terrible experience.

Anyway, the keyboard on my latest accordion isn’t bad- it’s very good actually. I just wondered if it was possible to fine tune it a bit more. I’m definitely not blaming the keyboard for how fast I can play tunes on it!

Hi Neo

Sorry for departing from your original intent.

Seems I was misguided by the terms "fast" and "light" which I linked to the keyboard itself rather than making a link to the sound. "Response" was the keyword.

Though I still believe there are "faster" keyboards than others (impacted by key geometry, key travel, spring forces, etc.) there is of course also a big difference in the fastness from pressing a key (i.e. opening the pallet) to a sound response - on a synth that param is called attack. I'm very sure changing anything on the keyboard itself will NOT impact the responsiveness/attack. This is a matter of reeds (their geometry, gaps between reed itself and the reed-block and valves). As you mentioned your new instrument comes with a Mano reeds (which the Pigini eventually features as well) I understand you're disappointed to notice a more or less remarkable difference. Again: Paul de Bra is way more into the details than I am, but from my limited background the reed response is mainly defined by the adjustment of the gaps between reed and reed-block. Fine-tuning this can be done but that's quite a work-package and needs a very experienced tuner/tech who exactly understands your desire and knows what he does.

Hopefully you don't have to go this path but have the option to return / trade-in your instrument against a "faster" one.

Sorry for departing from your original intent.

Seems I was misguided by the terms "fast" and "light" which I linked to the keyboard itself rather than making a link to the sound. "Response" was the keyword.

Though I still believe there are "faster" keyboards than others (impacted by key geometry, key travel, spring forces, etc.) there is of course also a big difference in the fastness from pressing a key (i.e. opening the pallet) to a sound response - on a synth that param is called attack. I'm very sure changing anything on the keyboard itself will NOT impact the responsiveness/attack. This is a matter of reeds (their geometry, gaps between reed itself and the reed-block and valves). As you mentioned your new instrument comes with a Mano reeds (which the Pigini eventually features as well) I understand you're disappointed to notice a more or less remarkable difference. Again: Paul de Bra is way more into the details than I am, but from my limited background the reed response is mainly defined by the adjustment of the gaps between reed and reed-block. Fine-tuning this can be done but that's quite a work-package and needs a very experienced tuner/tech who exactly understands your desire and knows what he does.

Hopefully you don't have to go this path but have the option to return / trade-in your instrument against a "faster" one.

Last edited:

Just as a matter of interest Neo have you checked the weight required to depress the keys

No, I haven’t done this- how would I go about checking?Just as a matter of interest Neo have you checked the weight required to depress the keys

Accordion revival tells you how to make a gauge

Okay, I’ll look that up- thanks!Accordion revival tells you how to make a gauge

isorry123

Member

Before drilling out wood … I would try to reduce the spring tension under the keys. The accordion revival website has a great write up for that.

Secondly, you probably want to reduce key travel range (reduce the action, for glissando and stuff), which could be as simple as an extra layer of felt on the key guides. Might have to bend key rods to if they get too uneven.

Adjusting key spring tension is an easy fix imo. Just a matter of getting the keys off the keyboard in order. Unless they have some wacky proprietary key design… you’ll notice the spring immediately after removing the key. It’s probably got a 90 degree bend relative - try taking that down to 45 degrees and see what it does.

Secondly, you probably want to reduce key travel range (reduce the action, for glissando and stuff), which could be as simple as an extra layer of felt on the key guides. Might have to bend key rods to if they get too uneven.

Adjusting key spring tension is an easy fix imo. Just a matter of getting the keys off the keyboard in order. Unless they have some wacky proprietary key design… you’ll notice the spring immediately after removing the key. It’s probably got a 90 degree bend relative - try taking that down to 45 degrees and see what it does.

Excellent- this is great advise and a much easier job that changing the mass of the underlay wood.Before drilling out wood … I would try to reduce the spring tension under the keys. The accordion revival website has a great write up for that.

Secondly, you probably want to reduce key travel range (reduce the action, for glissando and stuff), which could be as simple as an extra layer of felt on the key guides. Might have to bend key rods to if they get too uneven.

Adjusting key spring tension is an easy fix imo. Just a matter of getting the keys off the keyboard in order. Unless they have some wacky proprietary key design… you’ll notice the spring immediately after removing the key. It’s probably got a 90 degree bend relative - try taking that down to 45 degrees and see what it does.

I’ll try that on a couple of keys first and see how it is. Thanks a lot for this!

Ventura

Been here for ages!

ok, again, they need to have a clue what type brand model box

you are wondering on, otherwise much of this advise being dropped

could be the OPPOSITE of what you could should try to do

for instance, the itty bitty Hohner in your profile icon, to improve

the action on that one, wih it's short keys and pivot points, there

isn't a darn thing you COULD do except restore it to original condition

(the only optimal fix based on it's engineering limitations)

think about it.. in one example given, your under-key spring is going

to be re-bent from an assumed 90 degrees to 45, thus seriously

lowering it's range of motion relative to capturing some energy

when you push the key down.. so then there would be, perhaps,

only half as much stored energy available to pop the key back up

now let's see.. if the sluggishness is from dirt, gunk, warpage, twist,

sticky valve pads, or other physical issue, you would obviously need

every erg of energy you could get to push that lazy key back up..

not less.. so bend the spring wider.. but wait.. CAN it be bent at all

given the constraints of the engineering.. smaller boxes do not

have much luxury of lattitude in range of force, range of motion..

and lowering the total "lift" of a key requires a precision action mech..

again something not even remotely possible on an itty bitty short key accordion

so some of these proposed solutions would be done to improve the

SYMPTOMS

rather than the actual physical limitation or legitimate problem,

and that can only lead to bigger problems or a ruined instrument

you are wondering on, otherwise much of this advise being dropped

could be the OPPOSITE of what you could should try to do

for instance, the itty bitty Hohner in your profile icon, to improve

the action on that one, wih it's short keys and pivot points, there

isn't a darn thing you COULD do except restore it to original condition

(the only optimal fix based on it's engineering limitations)

think about it.. in one example given, your under-key spring is going

to be re-bent from an assumed 90 degrees to 45, thus seriously

lowering it's range of motion relative to capturing some energy

when you push the key down.. so then there would be, perhaps,

only half as much stored energy available to pop the key back up

now let's see.. if the sluggishness is from dirt, gunk, warpage, twist,

sticky valve pads, or other physical issue, you would obviously need

every erg of energy you could get to push that lazy key back up..

not less.. so bend the spring wider.. but wait.. CAN it be bent at all

given the constraints of the engineering.. smaller boxes do not

have much luxury of lattitude in range of force, range of motion..

and lowering the total "lift" of a key requires a precision action mech..

again something not even remotely possible on an itty bitty short key accordion

so some of these proposed solutions would be done to improve the

SYMPTOMS

rather than the actual physical limitation or legitimate problem,

and that can only lead to bigger problems or a ruined instrument

Hi,ok, again, they need to have a clue what type brand model box

you are wondering on, otherwise much of this advise being dropped

could be the OPPOSITE of what you could should try to do

Thanks, yes, I realise the options will vary depending on what instrument it is. If it was the little Hohner I wouldn’t be too concerned with adjusting much- it’s keyboard response is perfect as it is.

The one I want to possibly slightly adjust has 27 full size keys and it will have springs that could be adjusted which I think it something worth trying on a couple at least to see if that makes a difference. True, that will affect the forces acting on the key returning to its up position but I’m suspecting there is too much force there at the moment anyways so worth a try.

I have 14 accordions and have done various bits of restoration and repair on many of them- I wouldn’t risk doing irreparable damage to the instrument but good to know what position me options there might be.

I’ll attach a photo of the keyboard I’m talking about…

Attachments

Ventura

Been here for ages!

that is helpful.. also helpful is finding out you own 14 accordions total..

up until now it kind of seemed like you had only two points

of reference to compare..

the keyboard in question has lucite keytops, so it is modern

era construction, making gunk and wear less likely culprits..

the keys do not show any obvious warpage.. visual appearance

seems straight and level, so checking between the keys with a

feeler gauge should quickly rule out key to key friction/drag

it is a smaller keyboard and new enough that (assuming a pivot rod)

should not be difficult to pull that rod.. personally i bungee cord around

the section so the keys stay in place when sprung.. have you made

a chart noting which keys seem to be having a problem ?

thorough examination should reveal the necessary clues

up until now it kind of seemed like you had only two points

of reference to compare..

the keyboard in question has lucite keytops, so it is modern

era construction, making gunk and wear less likely culprits..

the keys do not show any obvious warpage.. visual appearance

seems straight and level, so checking between the keys with a

feeler gauge should quickly rule out key to key friction/drag

it is a smaller keyboard and new enough that (assuming a pivot rod)

should not be difficult to pull that rod.. personally i bungee cord around

the section so the keys stay in place when sprung.. have you made

a chart noting which keys seem to be having a problem ?

thorough examination should reveal the necessary clues

Similar threads

D

- Replies

- 2

- Views

- 2,723

D